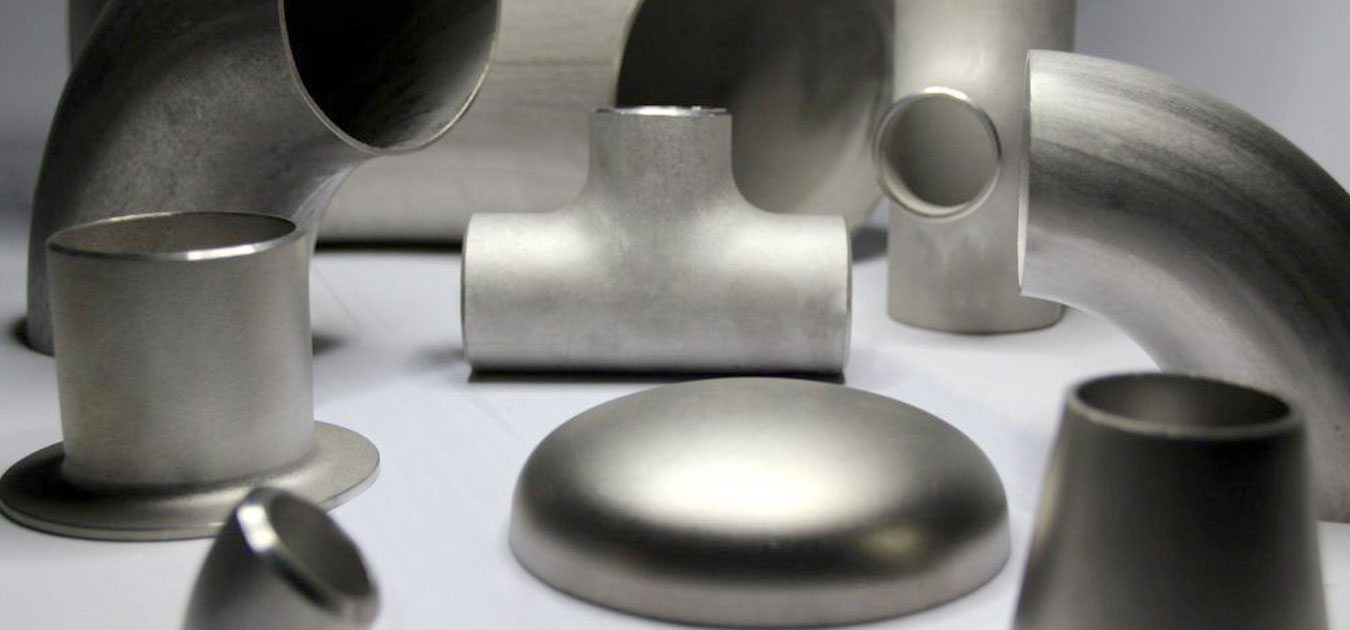

Butt weld fittings are integral components in piping systems, widely recognized for their exceptional strength and durability in various industrial applications. These fittings, meticulously engineered to seamlessly connect pipes and provide a leak-proof joint, play a pivotal role in ensuring the integrity of fluid transportation systems. Constructed from high-quality materials such as carbon steel, stainless steel, or alloy steel, butt weld fittings exhibit remarkable resistance to corrosion and temperature fluctuations, making them suitable for challenging environments.

Their precise dimensions and beveled ends facilitate a straightforward welding process, enhancing operational efficiency. These fittings are available in a myriad of sizes and configurations, allowing for versatile adaptability within diverse industries, including petrochemical, pharmaceutical, and power generation.

| MATERIAL | STANDARD | GRADE |

|---|---|---|

| Alloy Steel | ASTM A335 | WP5, WP9, WP11, WP12, WP22, WP91, WP92 etc |

| Stainless Steel | ASTM A403 | WP304/304L, 304H, 310, WPS31254, WP316/316L, WP317/L, WP321/321H, WP347/347H, WP904L |

| Duplex Super Duplex | ASTM A815 | S31803, S32205, S32750, S32760 |

| Nickel Alloy | ASTM B366 | WP20CB, WPH C276, WPN N02200/2201, WPNC N04400, WPNCI N0600, WPNCM N06625, WPNCIC10/12 N08810/8811, WPNCICMC N08825 ETC. |

| Carbon Steel | ASTM A234 | WPB, WPC |

| Low Temp Carbon Steel | ASTM 240 | WPL6, WPL3 |

| High Tensile Steel | ASTM A860 | WPHY 60, 65, 70 ETC |